New US Patent Awarded to VisionGauge® Tooth Checker™ to Check Manufactured Parts with 'Teeth' & Uneven Surfaces

The VisionGauge® Patented Tooth Checker™ tool is perfectly suited for quickly and accurately checking a wide range of parts across various industries.

• Major diameter

• Minor diameter

• Pitch diameter

• Thread pitch

• Helix angle

• Lead and trailing flank angles

• Root radii

• Taper

• Lead

• Circularity

• Etc.

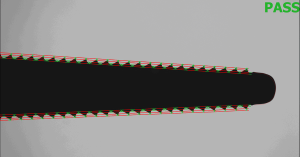

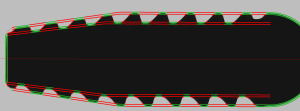

VisionGauge®’s Patented Tooth Checker™ tool is fully automated and completely independent of part orientation and clocking. Used in conjunction with a rotary stage, the crest and root points found by the tool can be used to calculate part runout. The tool is usable in both manual and fully-automated modes (i.e. within an automated program) and it has no limitations on part size, i.e. it can also be applied to parts that are larger than the optical field-of-view. The tool produces a PASS / FAIL result and also shows where the part passes and where it fails. It also has smart “Adaptive Thresholding” to automatically disregard point imperfections.

VisionGauge®’s Patented Tooth Checker™ tool is perfect for quickly and accurately checking a wide range of parts, including:

• Bone screws

• Medical rasps

• Gears

• Fluted instruments

• Threads & fittings

• Etc.

VisionGauge®’s Patented Tooth Checker™ tool is easy to setup and very powerful. It is fast & accurate and completely eliminates operator subjectivity. It can be used to collect complete inspection data, both pass / fail results and measured values.

VisionGauge®’s Patented Tooth Checker™ tool allows manufacturers to automatically check parts with teeth, uneven surfaces, and similar complex geometries, across a wide range of industries. It allows manufacturers to increase productivity, reduce costs, overcome labor scarcity, and get all the benefits of VisionGauge®, 24/7. It provides manufacturers with a real advantage in today's competitive market.

To learn more about the benefits of the VisionGauge® Digital Optical Comparator, please contact VISIONx, INC., either by visiting the web site at www.visionxinc.com or by contacting info@visionxinc.com.

VISIONx INC. specializes in automated imaging, visual inspection and high accuracy measurement solutions sold worldwide and is the manufacturer of the VisionGauge® Digital Optical Comparator.

Patrick Beauchemin

VISIONx, Inc.

+1 514-694-9290

info@visionxinc.com

Visit us on social media:

Facebook

X

LinkedIn

YouTube

The VisionGauge® Patented Tooth Checker™ Tool Overview

Distribution channels: Automotive Industry, Aviation & Aerospace Industry, Healthcare & Pharmaceuticals Industry, Manufacturing, Technology

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release